Product Carbon Footprint

Introduction

Introduction

A Product Carbon Footprint (PCF) is a means for measuring, managing and communicating greenhouse gas (GHG) emissions related to goods and services. A carbon footprint is based on a life cycle assessment (LCA) but focuses on a single issue which is global warming.

Working mode

Working modeFrom a Carbonstop perspective the following guidelines should be considered in order to obtain a resilient and meaningful PCF:

-

Consideration of more than one sustainability indicator

Comprehensive sustainability assessments of products include environmental, economic and social criteria. Greenhouse gas emission alone are not enough, even when focusing on the environmental impact of a product only. Therefore we recommend multi-criteria assessment tools to obtain a holistic view like our carbon accounting and management platform (CAMP).

-

Analysis of the whole life cycle of a product

A cradle-to-gate PCF offers only a limited view on the emissions related to the life cycle of a product. The complete assessment of the whole life cycle within properly defined system boundaries, taking the use and disposal phase into account, enables products to be compared and shows options for action. This needs cooperation along the complete value chain.

-

Follow internationally recognized standards and rules

Our PCF calculations are based on general life cycle assessment standards like ISO 14040 and 14044 and the Greenhouse Gas Protocol Product Standard.

-

Use of data of high quality to calculate a meaningful PCF

The quality of PCF data relies strongly on the quality of input data. In general we prefer to use data derived from our own processes (i.e. primary data). These data are updated regularly, if the impact on the PCF is significant. We strive to use primary data from our suppliers and have to rely on industry average data where no supplier-specific information is available.Our PCF calculations are based on general life cycle assessment standards like ISO 14040 and 14044 and the Greenhouse Gas Protocol Product Standard.

Cases

Cases

Carbonstop was elected as board member of first council of carbon label industry innovation alliance

Incom Clothes & Handbags

Carbonstop quantified the carbon emission reduction of Incom products--- clothes and handbags, which were made from recycled PET bottles. Besides, Carbonstop designed specific QR code to present the final results.

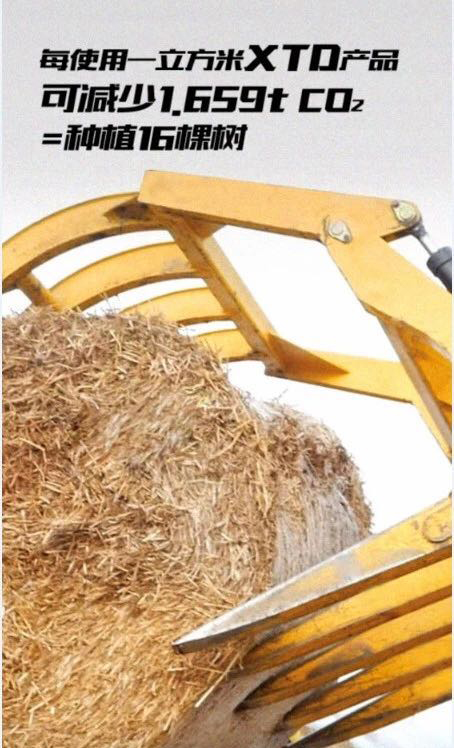

Renew Material XTD Board

Carbonstop calculated carbon emission reductions of XTD board, which is composed of up to 95% straw material. Besides, carbonstop also certificate the product as low-carbon products. The methodology follows the standards "CM-100-V01 carbon emission reduction methodology of waste agricultural straw replace wood producing board project ". Every m3 XTD board will reduce 1.6588 t CO2e.

Zhaoyi Envelope

Carbonstop quantified the carbon emission reductions of Zhaoyi envelope. This envelope can be reused for 5 times due to its special design. Compared other normal envelope, the Zhaoyi envelope reduced carbon emission in the whole life cycle. Carbonstop quantified the differences.

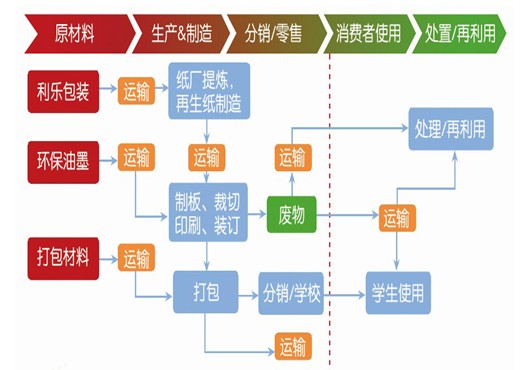

Ecofroggy notebook

Ecofroggy invited Carbonstop to quantify the carbon footprint of their products. Based on PAS 2050 and ISO14040, Carbonstop calculated the carbon footprint of per copy of notebook. The notebook was 32k with 12 page and weight of 29 g.

Carbonstop chose proper boundary, did the field research of paper production and collected activity data of production and printing process.After scientific accounting, the carbon footprint of the notebook was 139.54 gCO2e.

Jiangxi Wengang Low-carbon Calligraphy brushes

Jiangxi Wengang calligraphy brushes were produced by hand rather than machine. Carbonstop calculated carbon footprint of the brush from material to final product. The footprint of the brush was 261.7 gCO2e.

Service plan

Service plan